News & Events

15 Juli 2020, 10:11

15 Mei 2012, 14:51

15 Mei 2012, 14:36

15 Mei 2012, 14:51

15 Mei 2012, 14:36

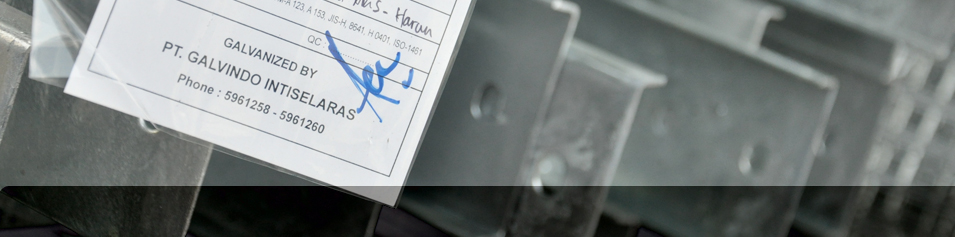

Process Galvanizing

.jpg)

| Preparation | Fluxing Quality |

| Hot Degreasing | Drying |

| Water Rinsing | Dipping : 530 0 C Centrifuging, 450 0 C Constant |

| Acid Pickling | Quenching / Pendinginan |

| 1st Water Rinsing | Inspection / Testing |

| 2nd Water Rinsing |

Design the right to produce good quality galvanized. Zinc will not react with the steel / iron to form a surface layer of galvanized steel except / iron is absolutely clean.

All parts are filled with air should be ventilated to allow air and moisture can get out of the material steel / iron in the hot zinc dipping into the liquid.

Material steel / iron that must be considered to be dipped in hot zinc liquid can enter the cavities and the air circulation so that the material of construction steel / iron may sink into the hot liquid zinc and can reach all surfaces during the dyeing process.

The principle of the ventilation channel is to avoid trapping chemicals in the chemical cleaning process that can cause an explosion when the process of dyeing with hot liquid zinc.

The principle of the drainage / draining is if construction steel / iron is inserted into the liquid chemical or hot liquid zinc, the liquid should be able to flow freely in and out without a hitch.

The process of drafting and structuring of construction steel / iron which has passed inspection draining vents and holes in a way associated with the position on supports 45-degree slope.

The tool is a wire bundle, jig, hanger and chain.

Caustic Cleaning

Caustic soda is a liquid with a temperature of 80 degrees Celsius. Used to remove organic materials such as dirt, oil, lacquer paint, and the fat attached to the material of construction steel / iron, made during the immersion (- +) 20 minutes.

Rinsing

The process of flushing material steel / iron in the water prior to rust removal process.

Acid Pickling

The immersion material steel / iron chloride into the acid solution for 30 minutes to remove scale and rust.

Rinsing

Construction material of steel / iron that has been clean from dirt and rust and then rinsed in a tub filled with water to remove residual acid solution chorida and drained.

Fluxing

Construction material is the process of steel / iron is dipped into the liquid flux to remove oxides and rust and helps prevent oxidation during the process material metallurgical steel / iron is dipped into the liquid zinc.

Drying

After the construction material steel / iron is dipped into the liquid flux, then the construction material steel / iron is drained into a tub with a drying temperature of 150 degrees celsius. This is a preparation temperature of the steel construction / steel before galvanizing process.

The process of Hot Dip Galvanized

material of construction steel / iron which has passed through the drying process is then performed the dyeing material of construction steel / iron into a bath of liquid zinc with temperature 445-455 degrees C.

During the dyeing process of the construction material steel / iron into a bath of liquid zinc there will be a process called the metallurgy, the liquid zinc will bind to the material of construction steel / iron alloy layer formed Zinc Once removed from the dyeing bath.

Quencing

Construction material steel / iron that has been coated with Zinc, then dipped into a solution of chromat to provide a layer to make it more durable and reduce pressure on the temperature for rapid handling.

Infection after the process of Galvanis

At this stage it will do a careful examination of the layer thickness, durability, and uniformity of display material steel / iron.