News & Events

15 Juli 2020, 10:11

15 Mei 2012, 14:51

15 Mei 2012, 14:36

15 Mei 2012, 14:51

15 Mei 2012, 14:36

Quality Test

At this stage it will do a careful examination of the layer thickness, durability, and uniformity of display material steel / iron.

In this case, we are very concerned about factors - a critical factor in galvanizing process thoroughly.

HDG is a 'self inspecting proccess' that relies heavily on the correct design to produce a good quality. The fundamental difference between HDG with the HDG coating of paint should be applied to the surface of the workpiece which has been prepared to perfection.

HDG is a 'self inspecting proccess' that relies heavily on the correct design to produce a good quality. The fundamental difference between HDG with the HDG coating of paint should be applied to the surface of the workpiece which has been prepared to perfection.

- Will not react with zinc to form a layer of galvanized steel, except the steel surface is really - really clean,

- Galvanized coating will not be formed if the Zinc does not stick perfectly to the steel.

- Galvanized coating will not be formed if the temperature is between 450-460 zinc is degrees Celsius.

- Workpiece can not be galvanized if the size does not fit with preparation tanks and galvanized the existing boiler.

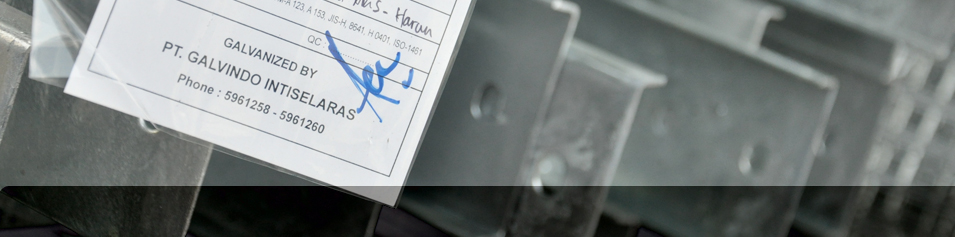

With these principles, the test quality galvanized process in PT. Galvindo Intiselaras covers the entire process in a way carefully.

.jpg)

Factors that substantial partner in the design for galvanizing categorized into 4 groups:

1. ventilation

2. The principle of Sewers (draining)

3. Dimensional unstable

4. design

Quality Standard

Quality Standard used PT GALVINDO INTISELARAS:

SNI 07-1953-1989 ,

SNI 07-7033-2004 ,

EN ISO 1461 ,

AS 1650-1989 ,

ASTM A 153 A 123,

JIS H 8641 H 0401